Institutional Presentation

Audio Visual

Policy Briefs

Policy Brief March 2023

Innovative & Impactful Approach for a Water-Smart Industrial Emissions Directive

Scientific Publications

IWAYS - Recycling of Heat, Water and Material across Multiple Sectors: Ceramic, Chemical and Steel Industry

In the framework of the iWAYS project, a synergy between energy and water reclamation and exploitation is addressed by means of the development and the installation of a wide array of technologies in three different industrial sectors: ceramic tile manufacturing, aluminium fluoride production and steel tubes manufacturer. The aim of the project is the creation of customized and integrated systems to achieve a substantial reduction in the thermal waste and in the freshwater consumption; this is the principal challenge the iWAYS project is solving by developing a set of technologies capable of recovering water and energy from challenging exhaust streams for productive use in the industrial processes. iWAYS systems will then treat steam condensate to meet the water quality requirements of each industrial process, while the recovered heat will be used to reduce primary energy consumption. iWAYS will recover additional materials from flue gas such as valuable acids or particulates, improving the production’s raw material efficiency and reducing detrimental emissions to the environment. The iWAYS technology will provide a reduction in the freshwater consumption greater that the 30% in each industrial case; with regards to the energy recovery, iWAYS will recover 6 GWh/y in the ceramic sector, more than 5 GWh/y in the chemical scenario and approximately 1 GWh/y in the steel sector. The iWAYS solution will have a payback lower than 5 years.

Development and Evaluation of Corrosion Resistance and Hydrophobic Properties of Thermal Sprayed Coatings over Carbon Steel

IVarious industrial parts and equipment made of steel need to withstand demanding conditions. In order to increase performance and lifetime, surface processing and functional coatings can be applied. In this study we report on the evaluation of coated carbon steel with commercial corrosion-resistant powders Diamalloy 4276 and Woka 7502 by Oerlikon Metco, using thermal spraying. Further functionalization is performed by rendering thermal sprayed surfaces syperhydrophobic via gas phase deposition of trichloro-1H,1H,2H,2H-perfluorooctyl silane, (PFOTS). Electrochemical impedance spectroscopy, contact angle and water condensation studies reveal the protective properties of coatings prepared by both materials as well as the superiority of Diamalloy 4276 based coatings. Corrosion was evaluated under a harsh 20% w/w H 2 SO 4 environment. Rendering the coating superhydrophobic improves water condensation under the tested conditions of high (80%) relative humidity.

Construction, Evaluation, and Performance of a Water Condensation Test Unit

The study of water condensation phenomena is important in order to evaluate the performance of materials and coatings employed in the fabrication of waste heat recovery units including heat exchangers, heat pipes, condensing economizers and related functional surfaces. Fast evaluation of lab-scale samples is important during research and development of coatings for wetting phenomena under controlled, reproducible, and stable humidity and temperature conditions of both sample and environment. To study these effects, we report on the construction of a lab-scale condensation chamber, along with its evaluation and benchmarking with superhydrophobic coatings on stainless steel using perfluorooctyl silane (PFOTS). A working unit has been successfully fabricated and applied in a highly responsive device capable of recording the condensation performance of flat specimens under controlled conditions. Sample temperature was maintained with 0.10 °C deviation. The humidity response time of the chamber is 17.2 s per degree of RH% while the maximum relative humidity variation is +/- 3.2%RH. The unit successfully delivered valuable data over hydrophillic, hydrophobic and superhydrophobic surfaces. Data useful for studying open research issues such the relationship of contact angle and condensation phenomena.

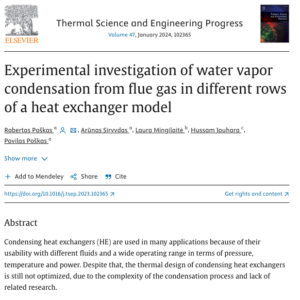

Experimental investigation of water vapor condensation from flue gas in different rows of a heat exchanger model

Condensing heat exchangers (HE) are used in many applications because of their usability with different fluids and a wide operating range in terms of pressure, temperature and power. Despite that, the thermal design of condensing heat exchangers is still not optimized, due to the complexity of the condensation process and lack of related research. This paper presents results of experimental investigations of biofuel flue gas water vapor condensation on vertical tubes in different rows of a tube bundle in a crossflow. The effects of water vapor mass fraction, inlet flue gas temperature and the Reynolds number on heat transfer when the inlet cooling water temperature and flow rate are constant were analyzed. The results obtained showed that the main parameters which had the most influence on the condensation process were the water vapor mass fraction in the flue gas and its temperature at the inlet to the test section. In the range of inlet flue gas Reynolds numbers investigated, the Re effect on heat transfer was not as significant as the effect of the parameters indicated above. However, the Re number had some influence on the heat transfer variation along the inline tube bundle. A comparison of the average Nu number in the case of dry air with the experimentally determined average Nu number, even with low condensable gas mass fraction (6 %), showed that it increased considerably. A correlation was proposed, which helps to determine the average Nu number for the heat exchanger in the range of experiments performed.

Experimental investigation of water vapor condensation from hot humidified air in serpentine heat exchanger

Condensing economizers are used in industry and power plants for waste heat recovery. Despite widespread use, their thermal design is still not optimized due to the complexity of the condensation process especially when non-condensing gasses are prevalent. This paper presents an experimental study of water vapor condensation on the vertical tubes of a serpentine bundle in a humidified air crossflow at water vapor mass fractions of 10% and 20%. The analysis showed a clear dependence of the efficiency of the condensation process on the humidified air inlet temperature and Reynolds number, and the efficiency increases as these parameters decrease. Condensation efficiency also depends highly on flow humidity especially in the region of higher Reynolds numbers. A comparison of the average Nusselt number in the case of dry air with the experimentally determined average Nusselt number is also presented, and showed a uniform increase in the Nusselt number as the inlet temperature of the humidified air decreased.

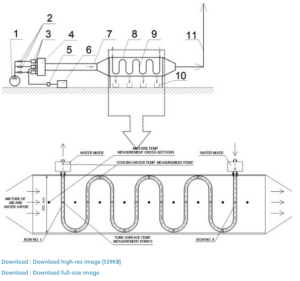

CFD analysis for membrane distillation optimization for wastewater treatment

In the context of circular economy and of decarbonisation of the society, one of the uprising techniques for industrial wastewater treatment is the use of Membrane distillation (MD) system, because of its capabilities such as low carbon footprint, and being able to be coupled with waste thermal energies. However, the main drawback of these systems is the temperature polarization phenomenon which can lead to performance reduction. To overcome this problem, geometry modifications such as adding spacers in the system is considered. Thus, a simple geometry is built to study the thermal distribution through the system, and then the effects of adding spacers with different configurations is here investigated using Computational Fluid Dynamics (CFD) analysis. The different spacer configurations are characterised and their effect on MD performance are tested. The optimal configuration will be used, via 3D printing to confirm finding on an experimental setup on upcoming study. To read conference proceedings of SimHydro 2023, p. 208, click on image to the left.